- Home

- Lead Time

- Contact Us

- About Us

- Track Specs

- FAQ

- Why BestTrack®?

- Pictures/Videos

- Track Prices

- Order Now!

- Champ Timer

- Leveling Kit

- Lift/Leveling Kit

- Remote Start Gates

- The Super Loop

- Space Derby® Tracks

- Test Track

- Trophy Display Stands

- Car Carriers

BestToss® Bag Toss Game

Timers and other Pinewood Links - Strength

- Our Curve!

- Stop System

- Printable Info

- Why We Don't Anodize

- References

- Assembly Manuals

- Storage Box Plans

- Warranty

- Thank You Cards!

Why We Don't

Anodize

We will occasionally get the question as to whether we anodize our track. At the this time we do not, and here are the reasons:

1. Anodizing is expensive. We want to provide you with a top quality, durable track, at a reasonable price. We feel that anodizing would unnecessarily increase the cost of our track.

2. Anodizing adds little benefit. Although you can remove fingerprints a little easier on an anodized track, we have found that a spray cleaner like "Simple Green" works wonders at removing fingerprints and graphite from your track, and is much more cost effective.

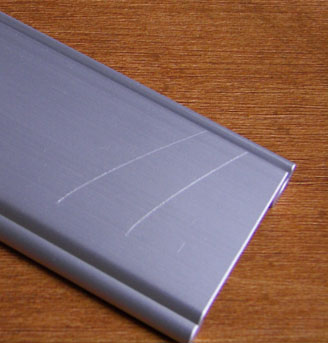

3. Anodized aluminum still scratches easily. Look at the picture below. This picture is a piece of clear anodized aluminum, scratched very easily with a screwdriver. One slip with a screwdriver or wrench and you have a scratched track. On our track, however, all of the fasteners are on the bottom of the track. If you were to accidentally slip with a tool while assembling a BestTrack, the scratches would be on the bottom side, out of sight. Some tracks use screws from the top side, which could lead to obvious scratches if your screwdriver slipped while assembling the track.

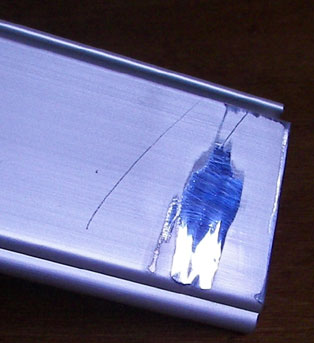

4. Scratches are impossible to remove in anodized aluminum without affecting the anodizing. Let's say you scratch your anodized track. How do you remove the scratch? Most likely you will try buffing or using very fine wet/dry sandpaper to smooth out the scratch. This will remove the anodized surface from the scratched area, resulting in a very different look. The picture below shows what happens when a buffing wheel is used to try to remove the scratch.